ECS Synchronator

The electrically impulsed clocking in clocks supplied by ECS had high resistance coils requiring a pulse of 36 volts once every minute. This is different from the standard slave dials which had low resistance coils, were impulsed every 30 seconds, and were set up by the current flowing in the circuit, not the voltage. Therefore, the clocking in clocks could not be simply added to the slave dial circuit.

There were two ways to generate the required 36 volt, one-minute pulse.

- One was by using an impulse converter connected in the normal slave circuit of a master clock (click on Impulse Converter on the left for details).

- The alternative, where a master clock system was not already in place, was to use a device called a Synchronator.

|

|

|

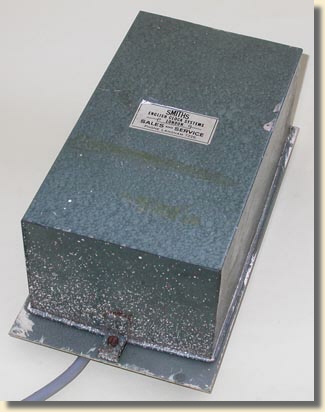

The Synchronator was housed in a metal box.

|

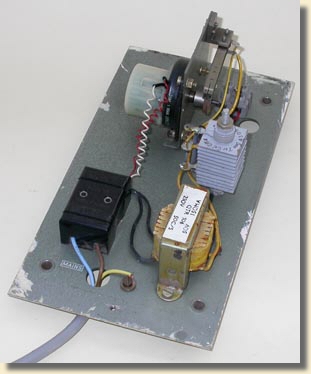

A synchronous motor running from the AC mains supply drives a cam which closes a contact set for a few seconds once per minute and connects 36 volts from a mains transformer via a rectifier to the clocking in clock.

|

|

|

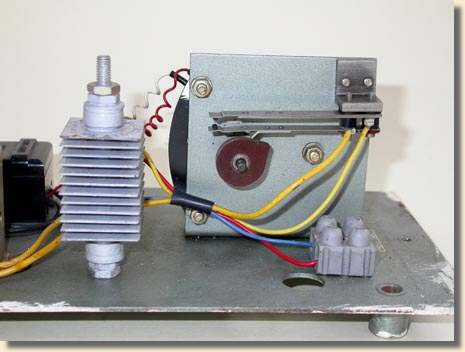

The cam and contact set.

|

|

|

|

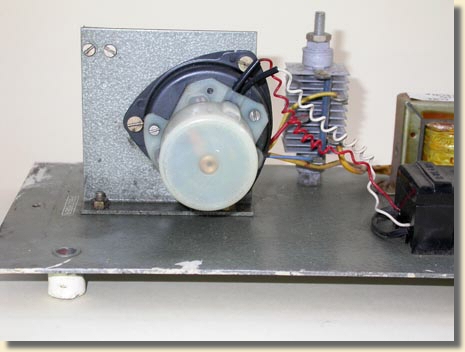

The synchronous Smiths motor.

|

|

|

|